Optical fibers are among the top choices for usage in today’s metros together with remote networking systems. As we have mentioned earlier, the optical fiber is available in different standard dimensions.

For this reason, they need to be attached together or spliced to fit the needs of a network. Additionally, the fiber edges need to be fixed on compatible connectors before ending, a process which is known as “connectorization”. Both splicing and connectorization, are vital for setting the installation expenses and controlling the system’s efficiency.

Splicing in this case, describes the special alignment of the cores of two optical fiber parts to facilitate an even junction which will allow light messages to travel without any high level of attenuation. There are two distinct techniques utilized for uniting fibers together, described as follows:

Splicing

Splicing is used for offering life-lasting fiber connections that take place between fiber parts in a networking system. These are further divided into secondary categories, depending on their cost and efficiency. The most commonly used categories are the following:

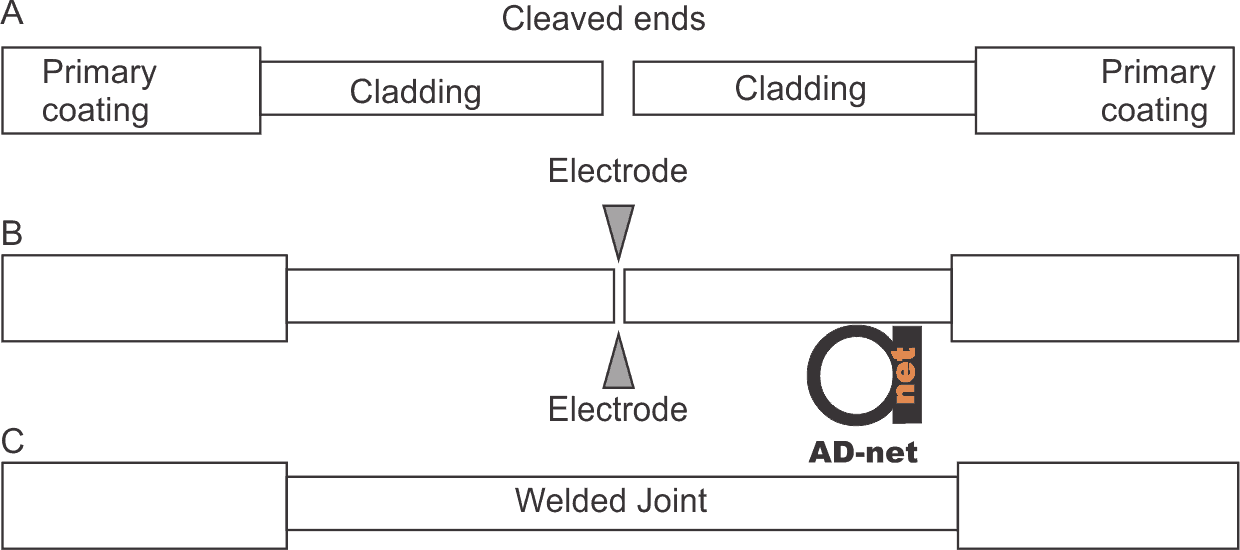

Fusion Splicing

Fusion splicing is a fiber joining technique that is trustworthy, speedy, and provides low attenuation while fiber to fusion splicing provides the same benefits. Fiber to fiber joining also builds an even connection between the fiber edges. The fibers are joined together with heat or fusion of the ends together using an electrical device. Fusion splicing is great for offering a quality connection of the fiber ends with the lowest degree of loss (covering the range of 0.01 dB to 0.10 dB for single mode fibers) while controlling the risk of reflections.

Figure 1: 3 main steps in fusion splicing process

Mechanical Splicing

Mechanical splicing is another technique for creating a life lasting joining of optical fibers. Initially, this method wasn’t the best in terms of reliability and quality of connections as it produced a high level of losses and below satisfactory efficiency. Due to the progress of modern technology, mechanical splicing and is results are vastly improved.

A basic advantage of this splicing technique is that it’s less costly and more easy to create joins. Mechanical splicing is employed to create life lasting connections between optical fibers by grasping the fibers in alignment establishment and decreasing the loss and reflection with a clear gel or glue that fits the optical attributes of glass material.

In general, mechanical splicing technique leads to higher risk for losses and reflection comparing to fusion splicing and due to the fact that fibers are balked to keep them in place, they do not produce high fiber maintenance and pull-out integrity.

It’s possible to perform mechanical splicing without having to crimp the fibers as short lasting splices for checking uncovered fibers with OTDRs. The thing is, most splice jointers utilize a mechanical splice inside and for this reason, the systems and procedures mentioned earlier apply to these as well.

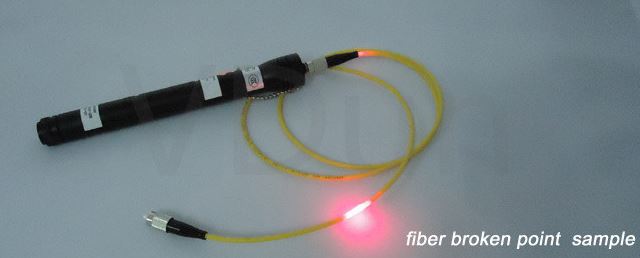

The main pro of mechanical splicing is that no fancy or costly machinery is required to create the splicing. Just a few tools for cable setting up are all you need for making this possible–a Visual Fault Locator may also come handy for improving the localization and efficiency of splicing.

Figure 2: Visual Fault Locator