Copper based cable connectors typically are connected to the cables using technology that will hold them together: punch-down, or crimping. Optical fiber requires more “gentle” approach for the proper connection establishment. Typically, fiber cable manufacturers specify connection methods, required materials and tools necessary for the job. In some cases cables are having factory installed connectors, however it is possible to terminate cable in the field if all the necessary tools are available.

Connector installation is done with special tool “receptacle” where the core of the fiber cable is aligned with the core of the connector. It is important to note that during connector installation core should be perfectly aligned. Even slight angle might disrupt signal and data transmission. Also it is important to check that core surface was not damaged and does not contain scratches, cracks, or protrusions. This applies both to cable and connector end. The angle issue is easily solvable by adding a sleeve that fiber cable should go through before going into “receptacle”. In order to fixate the connector at the end of the cable one of two most common technologies is used: gluing or crimping.

Gluing is done with one of three adhesives. First type of adhesive requires heat to harden and keep in place. It is called heat-cured adhesive. It needs to be applied to the necessary point and placed in the oven for about 20 minutes. this method is time-consuming and requires additional equipment to be available in the field – the oven. However multiple connectors could be heat-cured at the same time.

Second gluing option is the UV-cured adhesive. Technology is similar to the one used by dentist – instead of oven-heating the UV light is used. It is also less time-consuming, since it takes about 1 minute for the adhesive to be “baked” in place by UV light.

Third gluing solution relies on chemical reaction between the components. Anaerobic-cured adhesive is done in several steps:

- Resin material injection in the ferrule;

- Hardener catalyst application to the optic fiber;

- Fiber insertion in the ferrule where chemical reaction happens.

Whole chemical reaction takes about 15 seconds to finish.

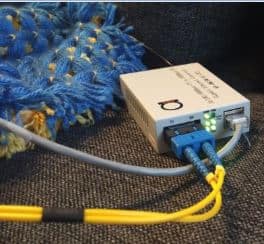

Alternative to gluing is crimping. Crimping is the connection solution where the ends of the fiber and connector are kept together with positive mechanical force. Critical part of crimping is the polishing step. It is very important to follow the manufacturers instruction and use only recommended cleaning an polishing kits. Majority of failures in the field happen due to dirt or debris on the fiber.

Figure 1. Crimping connector

Some of the fiber cable manufacturers come up with alternative solutions for the connector installation. These connectors are faster and easier to install, however high cost and questionable reliability does not speak in their favor.